Sensor modelling

The sensor has

been calibrated and therefore it is now possible to use ISET to model the

sensor output given a map of reflectance.

First we need to

convert a pdf file to a map of cmyk.

We also need to

compute the reflectance from any cmyk value.

We can then make a

scene in ISET with it.

Finally we model the sensor.

PDF

to cmyk:

Description of problem

An important

aspect of modeling the printer optical sensor is to accurately model its input.

The printing process starts when a user at a computer requests a page to be

printed. The specific page is at that time encoded in a high level page

description language format such as Postscript (PS), Portable Document Format

(PDF) or Encapsulated Postscript (EPS). A raster image processor is responsible

in converting this image representation to an image represented in the natural

color space of a printer i.e. in converting a PS, PDF or EPS file format to a

bitmap file in the CMYK color space. A bitmap file that allows us to represent

an image in its CMYK values is the Tagged Image File Format (TIFF). Hence the

goal of this stage is to produce the CMYK values for each pixel position, so

that they can be used in the next stage to interpolate the reflectance values.

Method used to solve the problem

It is

possible to convert a PS, PDF or EPS file to a TIFF file in the CMYK color

space following a number of simple steps. Already existing software packages

are used to solve this problem, which are free and open source.

The first

thing to note is that in creating the PS, PDF or EPS file format, we need a

printing device that is able to do that. For example the Adobe PDF printer can

be used, or depending which operating system you are using you might opt for

something different. In any case, the printer you are going to use for creating the PS, PDF or EPS file, must give

you the option to represent the image in the CMYK color space (for example, the Adobe PDF printer,

gives you that option in its advanced settings, see figure 1).

Figure 1 CMYK

color space in Adobe PDF Settings

Figure 1 CMYK

color space in Adobe PDF Settings

Once you have installed imageMagick, you can open the command line

prompt of your system (if you are using Windows just type cmd in the run

window). Navigate to the folder that contains test.pdf and type convert test.pdf test.tiff

Conversion

That’s it. A new file called test.tiff is

created. This is the CMYK color space representation of the page.

You can read this in MatLab using the

following command

Im = imread(‘test.tiff’,’tiff’);

CMYK to

reflectance models:

We now want to transform the CMYK values

obtained by the renderer into estimated reflectance data to simulate our

printed paper.

In this purpose, we used the data provided

by HP that gives us a measurement of the reflectance at 35 different

wavelengths for 1338 different CMYK values.

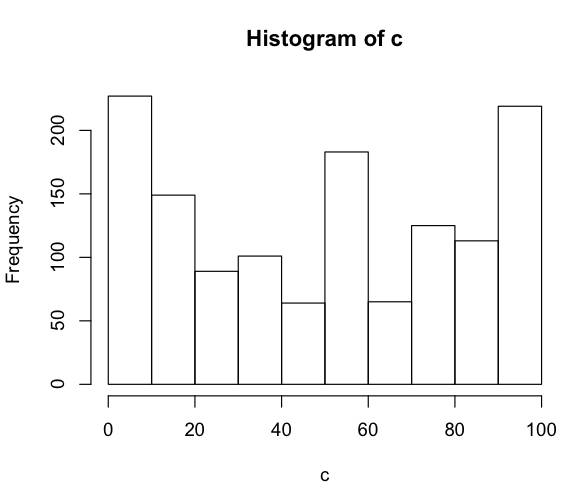

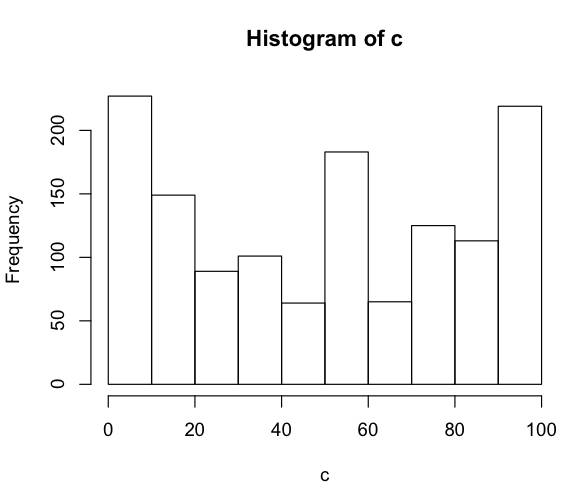

Let's first have a look at the repartition

of the data over the CMYK space. Here is the histogram of values for the C

values. (We have exactly the same histogram for the M and Y values).

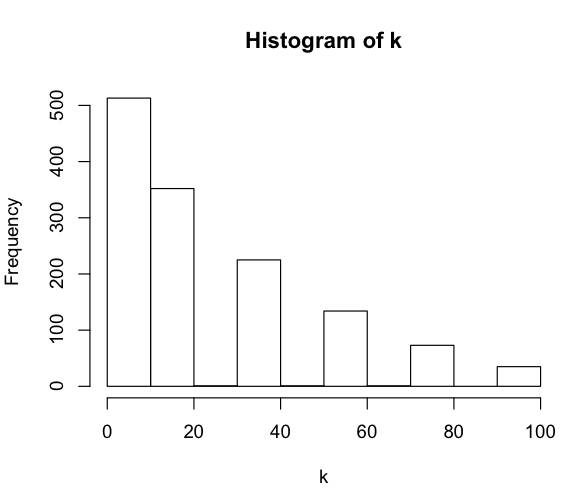

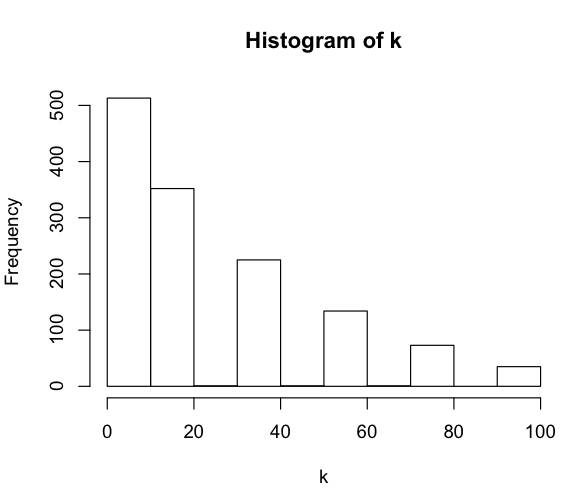

Here is the histogram the the K values:

We can see that the CMYK values provided globally cover the

entire space of possibilities even if we have less measurement with value K=100

that we have for K=0. This can be explained by the fact that when K is higher,

the color is much darker and changing the other value of C,M and Y do not make

much difference in the reflectance estimation.

With this repartition in mind, we developed

two models to fit CMYK values in reflectance datas.

1)

Nearest neighbor estimation or

locally linear model

The first model we developed is a locally

linear model that uses nearest neighbors to find the reflectance for a given

CMYK value.

Having our entire database of 1338 values,

we want to find a reflectance approximation for every possible CMYK values in

our space. In this purpose, given a new CMYK value, we will find the nearest

neighbors in the database and allocate each of them a weight depending on their

euclidian distance to our current value.

Then, computing the reflectance for our

current CMYK value consist of averaging the reflectances of the nearest

neighbors found with their respective weights.

As we can see from the previous histogram,

the database gives us a quite dense representation of the CMYK space, and then,

we believe this model is very well suited to approximate correctly the

reflectance values from any CMYK value.

As we can see here, we need to keep in

memory the entire database to compute the nearest neighbors and then the

reflectance estimation. For our study, this is perfectly reasonable but the

computation might be too high for a real-time application.

So we also decided to develop a global

linear model for fast computation.

2)

Log-linear model

Here, we will try to fit a globally linear

model on our data to see if we can represent our entire dataset by such a

family of models.

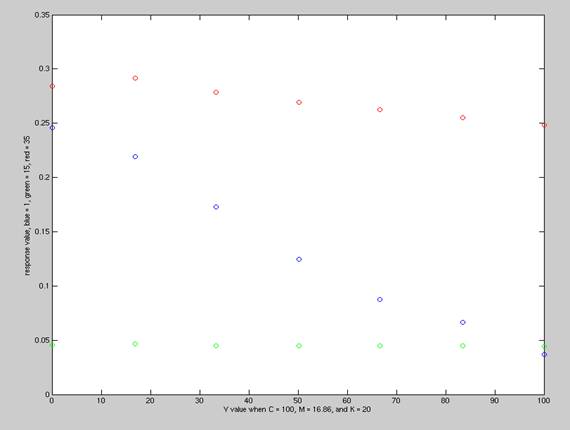

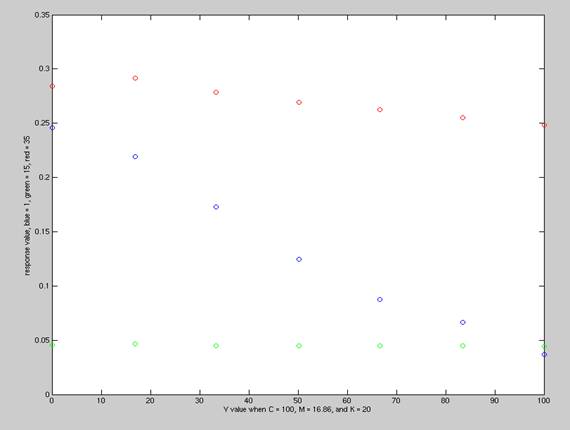

Let's consider three wavelengths from our

35 original wavelengths from the database and let's see if you can find a

linear correlation between the reflectances and the associated CMYK values.

For example, let's fix the C,M and K values

to some values and let's vary the Y values and plot the three reflectances for

those different Y values from our database.

Here is what we obtain:

We can repeat this experiment several times

fixing different values to gain the idea that we have a strong correlation

between the reflectances and the CMYK values and that relationship seems to be

linear.

In fact, after several model fitting

experiments, the conclusion is that a log-linear model provide the best

results. That is to say that for a given wavelength, we try to estimate the log

value of the reflectance as a linear function of the C, M, Y, and K values.

Let's consider a typical example. We

consider a specific wavelength (e.g. 560 nm) and we want to learn a log-linear

model given the CMYK values. For this simulation purpose, we used the R

programming language that provides the idea statistical toolbox.

Here is a summary of training a log-linear

model on the provided data.

Call:

lm(formula = log(ref) ~ c + m + y + k)

Residuals:

Min 1Q Median

3Q Max

-2.58477 -0.09752 0.03014

0.13710 0.78169

Coefficients:

Estimate Std. Error t value

Pr(>|t|)

Intercept -0.2882194

0.0201173 -14.33 <2e-16 ***

c -0.0041139 0.0002018

-20.39 <2e-16 ***

m -0.0100856 0.0002018

-49.99 <2e-16 ***

y -0.0175252 0.0002008

-87.28 <2e-16 ***

k -0.0206068 0.0002621

-78.61 <2e-16 ***

---

Signif. codes: 0 '***'

0.001 '**' 0.01 '*' 0.05 '.' 0.1 ' ' 1

Residual standard error: 0.251 on 1312

degrees of freedom

Multiple R-squared: 0.9562, Adjusted R-squared: 0.956

F-statistic: 4115 on 4 and 1312 DF, p-value: < 2.2e-16

What we can see from this summary of the

model is that the R-squared error is very close to 1, the F-statistics very

high and the p-value extremely small, proving that such a model fits very well

our original database.

What we can also see is that the four

values C,M,Y and K are important for our model ( all four are represented by

***, which means they are essential features of the model), which seems

perfectly intuitive.

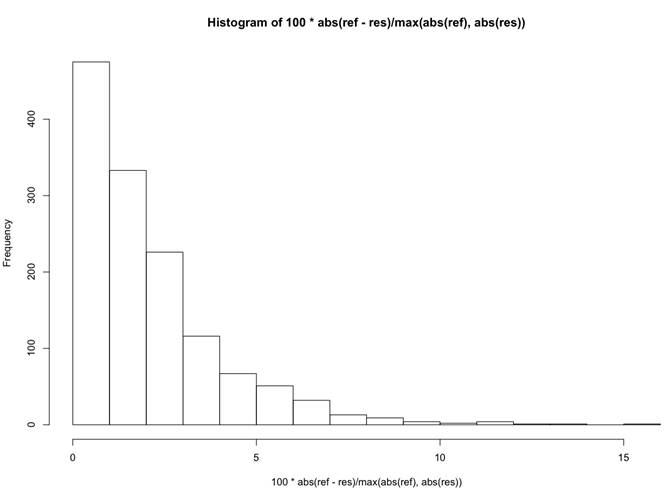

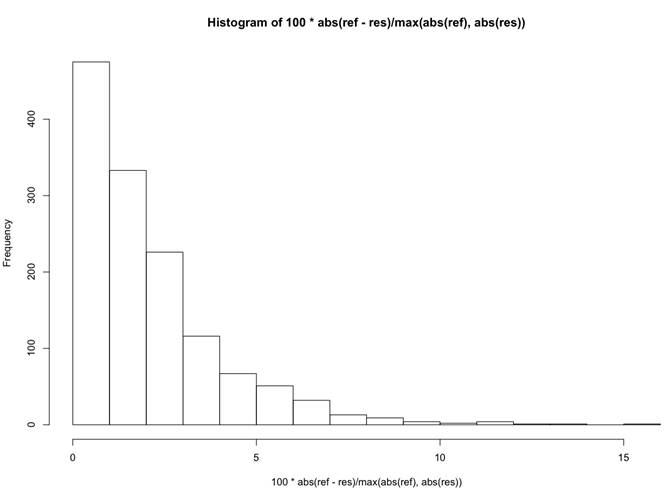

To see what it gives in term of error,

let's have a look at the percentage of error for the CMYK values from the

database with our model. Here is an histogram of the relative error:

What it shows is that for approximately 500 values (on 1338),

the model gives an approximation of the reflectance that is within 1% of error

from the exact value for a particular wavelength, which seems to be a good fit.

In we want to develop a real-time

application, it might then be faster to use this kind of model, for which we

only need 5 parameters per wavelength , so 5*35 parameters in total, which is

much smaller than the original 1338 values needed for the locally linear model.

Scene

model:

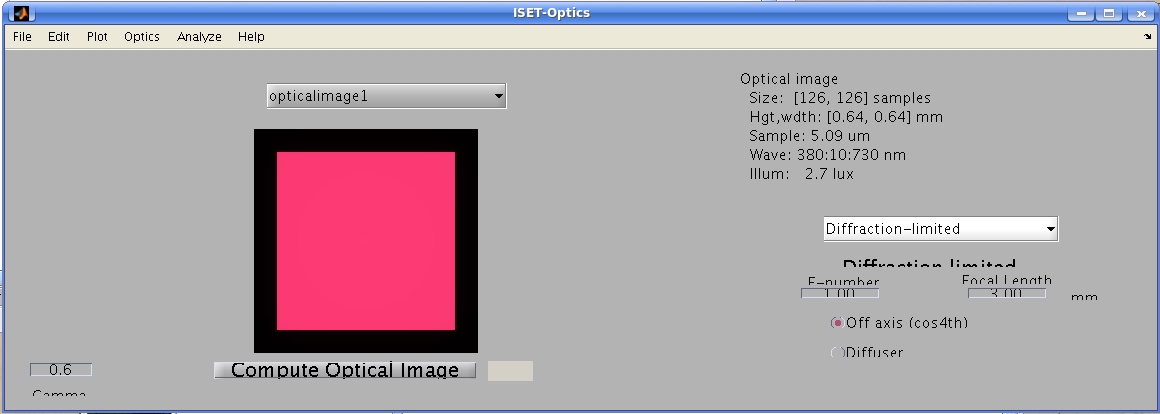

We can now take this map of reflectance and

read it in ISET as we would read a Macbeth chart. We add a light. Now, from the

reflectance, the light and the distance of the image, we can compute an ISET

scene.

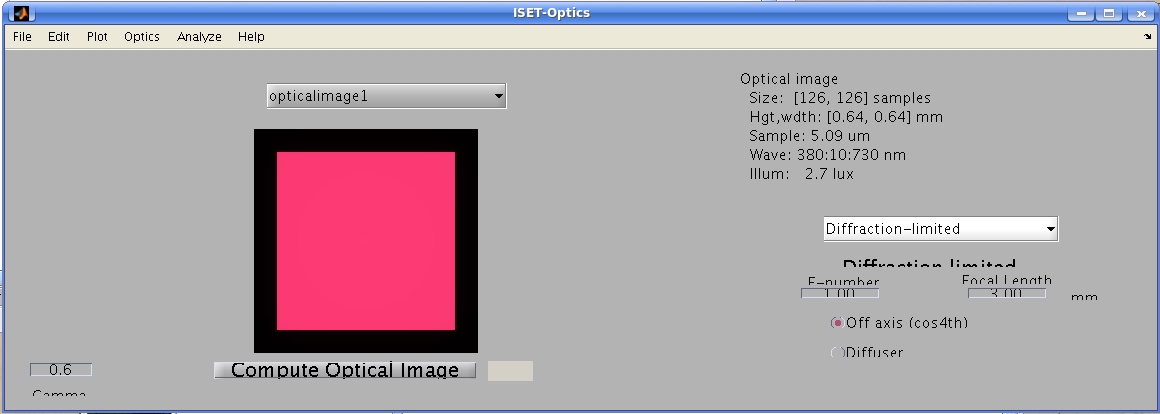

Optical image for a uniform patch:

Sensor model:

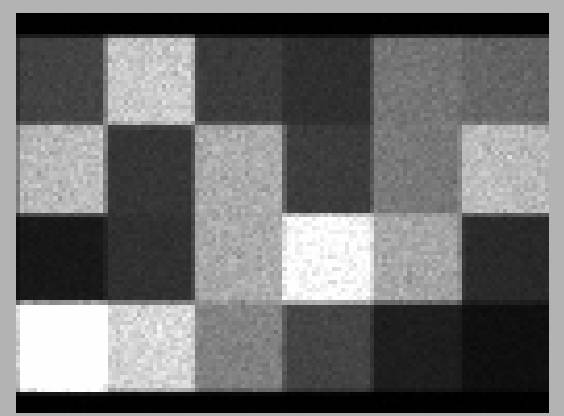

Now that we have determined the

characteristics from experiment, we can fit them into ISET to simulate the

sensor. We created quantum efficiency matrix based on the lab experiment and

configurated the sensor model to fit with the measurements (PRNU, DSNU, dark

current...)

This entire simulation process now provides

a framework for simulation purposes. Let's take an example of an original image

that we would like to print and measure visual information from it using our

sensor and optics model.

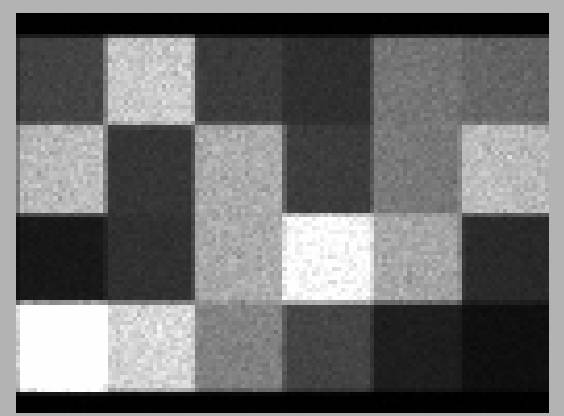

With our sensor and optics model, it is now

easy to simulate the output for this given image :

What is interesting to see from a global perspective

is that not all colors are discriminable. If you look at the patch on

coordinates (2,2) and (3,2) or (1,5) and (2,5), the colors from the original

Macbeth chart are perfectly discriminable. But, using this monochrome sensor

makes them undiscriminable from the sensor images.

The goal then is to be able to provide some

test results on which type of colors we are able to discriminate and also which

type of spatial details we are able to capture with our entire system.

Figure 1 CMYK

color space in Adobe PDF Settings

Figure 1 CMYK

color space in Adobe PDF Settings